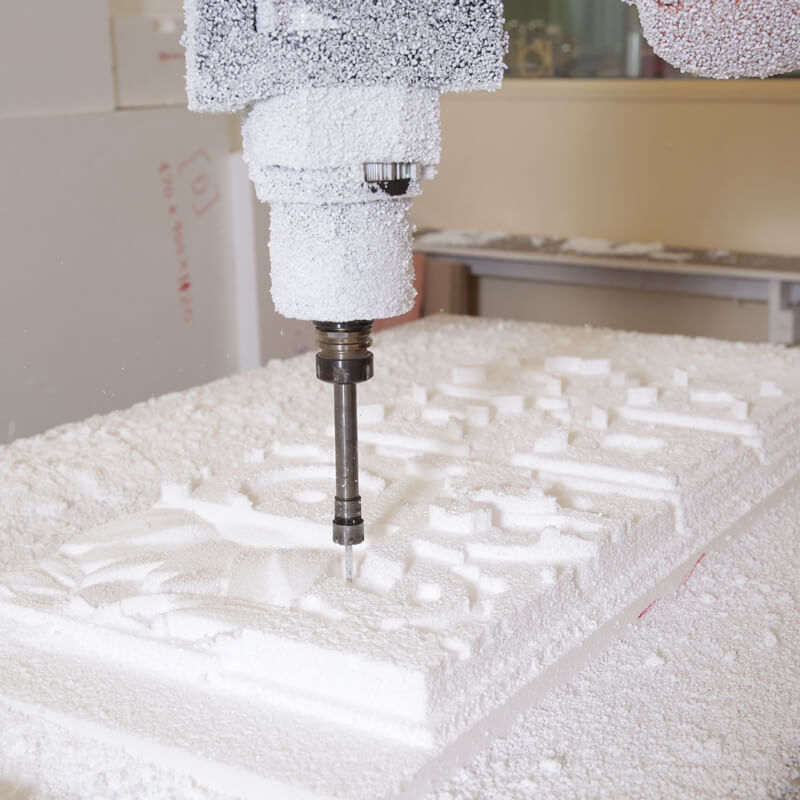

Team Visual Solutions takes pride in its ability to implement technology to automate processes. The CNC Milling Robot (KUKA) is a reaffirmation of this.

This Robot is an individually configurable machine tool that independently automates and performs all work steps in 3D. This enables us to deliver samples and finished sculptures with great speed, accuracy and precision.

Thanks to the high degree of automation available via this robot, our artists can focus on providing amazing finishes to the sculpted models on a large scale. This significantly reduces our turnaround times for digital renderings, in addition to elevating the efficiency of our production process.